Stay Connected: The Vital Role of Electrical Testing in Gurgaon’s Power Infrastructure

Introduction

Gurgaon, a bustling city in India’s Haryana state, is known for its rapid urbanization and thriving commercial landscape. With a rapidly growing population and increasing infrastructure demands, the power sector plays a vital role in supporting the city’s growth. To ensure the safety, reliability, and uninterrupted supply of electricity, electrical testing emerges as a crucial aspect of Gurgaon’s power infrastructure. In this article, we will explore the significance of electrical testing and its various types, emphasizing the importance of staying connected through robust testing procedures.

The Importance of Electrical Testing

Electrical testing is a comprehensive evaluation of various electrical components and systems to identify any potential issues or faults. It involves assessing the performance, integrity, and safety of electrical installations, equipment, and networks. In Gurgaon’s power infrastructure, electrical testing serves as a preventive measure to detect problems early on, minimizing the risk of electrical failures, accidents, and disruptions.

Ensuring Safety and Reliability

Safety and reliability are paramount when it comes to power infrastructure. Electrical testing helps in identifying potential hazards, such as faulty wiring, overloaded circuits, or damaged equipment, which could lead to electrical shocks, fires, or power outages. By conducting regular testing, power authorities and maintenance teams can proactively address these issues, ensuring the safety of both the electrical system and the people relying on it.

Types of Electrical Testing

There are various types of electrical testing conducted to assess different aspects of the power infrastructure. Let’s explore some of the essential testing procedures:

1. Visual Inspection

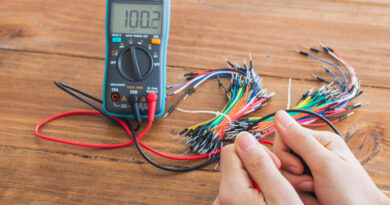

Visual inspection involves a thorough examination of electrical components, looking for any visible signs of damage, corrosion, loose connections, or improper installations. It serves as the first step in detecting any obvious issues before moving on to more advanced testing methods.

2. Insulation Resistance Testing

Insulation resistance testing measures the resistance offered by electrical insulation, such as cables and wires, against the flow of current. It helps identify any deterioration or breakdown of insulation, preventing potential short circuits or electrical leakage.

3. Circuit Breaker Testing

Circuit breakers are critical components that protect electrical systems from overloads or faults. Regular testing ensures that these devices are functioning correctly, allowing for timely interruption of faulty circuits and preventing damage to the system.

4. Transformer Testing

Transformers play a vital role in the power distribution network. Testing transformers helps ensure their proper functioning, efficient energy transfer, and insulation integrity. It involves evaluating parameters such as voltage regulation, impedance, and insulation resistance.

5. Grounding System Testing

Proper grounding is crucial to safeguard against electrical faults and ensure the dissipation of excess electricity. Grounding system testing verifies the effectiveness of grounding electrodes and connections, preventing potential electrical hazards.

6. Power Quality Testing

Power quality testing assesses the quality and stability of the electrical supply. It helps identify any voltage fluctuations, harmonics, or other power anomalies that could impact the performance of connected equipment and devices.

Frequency of Electrical Testing

The frequency of electrical testing depends on various factors, including the type of equipment, its criticality, and environmental conditions. It is recommended to follow industry standards and guidelines for regular testing intervals. Typically, annual testing is considered essential, but specific components may require more frequent inspections or testing.

Hiring a Professional Electrical Testing Service

To ensure accurate and reliable testing results, it is advisable to hire a professional electrical testing service. These experts possess the necessary knowledge, skills, and equipment to conduct comprehensive tests and provide insightful reports. They can help identify potential issues, offer recommendations for improvements, and assist in maintaining a robust power infrastructure.

Benefits of Regular Electrical Testing

Regular electrical testing brings several benefits to Gurgaon’s power infrastructure:

- Enhanced Safety: Identifying and resolving potential hazards reduces the risk of electrical accidents, protecting both people and property.

- Improved Reliability: By addressing issues proactively, electrical testing helps prevent unexpected breakdowns and power outages.

- Cost Savings: Early detection of faults and timely maintenance can save significant costs associated with major repairs or system failures.

- Compliance with Regulations: Electrical testing ensures adherence to safety standards and regulatory requirements, avoiding penalties or legal complications.

- Increased Lifespan of Equipment: Proper testing and maintenance extend the lifespan of electrical equipment, optimizing their performance and efficiency.

Conclusion

In the ever-growing city of Gurgaon, maintaining a robust power infrastructure is crucial for sustaining its rapid development. Electrical testing plays a vital role in ensuring the safety, reliability, and uninterrupted supply of electricity. By conducting various tests on different components and systems, potential issues can be identified and addressed proactively, minimizing risks and maximizing the efficiency of Gurgaon’s power infrastructure.

FAQs

1. How often should electrical testing be conducted? The frequency of electrical testing depends on factors such as the type of equipment and environmental conditions. Generally, annual testing is recommended, but more frequent inspections may be necessary for critical components.

2. Can visual inspection alone be sufficient for electrical testing? While visual inspection is an essential first step, it is recommended to conduct more advanced testing methods to ensure a comprehensive evaluation of electrical systems and components.