The Ultimate Guide to Effective Electrical Panel Testing for Safety and Reliability

Introduction

Electrical panels are the backbone of any electrical system, responsible for distributing power throughout a building or facility. Ensuring the safety and reliability of these panels is of utmost importance to prevent accidents and equipment damage. In this comprehensive guide, we will explore the necessary steps to conduct effective electrical panel testing, helping you maintain a secure and efficient electrical setup.

Understanding Electrical Panels

Electrical panels, also known as distribution boards or breaker boxes, receive electrical power from the main supply and distribute it to various circuits within a building. They contain circuit breakers or fuses that protect the circuits from overcurrent and short circuits.

Importance of Regular Testing

Regular testing of electrical panels is crucial to identify potential issues before they escalate into major problems. It helps in preventing electrical fires, equipment damage, and electrical hazards, ensuring a safe working environment.

Preparing for Electrical Panel Testing

Before conducting any tests, proper preparation is essential to ensure safety and accuracy.

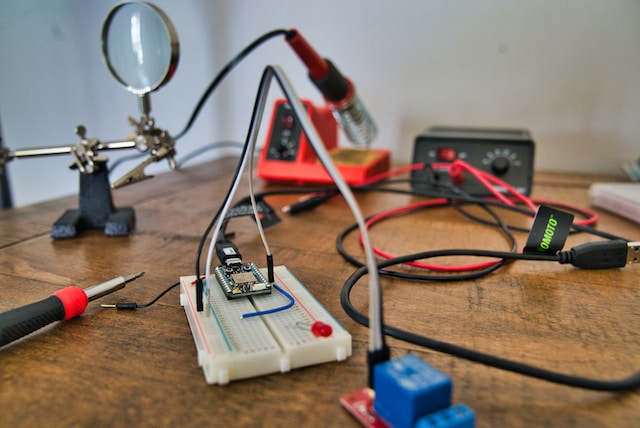

Gathering Necessary Tools and Equipment

Make sure you have the required tools and testing equipment, such as a multimeter, thermal imaging camera, voltage tester, and protective gear.

Ensuring Safety Measures

Safety should be a top priority during panel testing. Use appropriate personal protective equipment (PPE) and follow safety guidelines.

Shutting Down Power Supply

Before starting the testing process, turn off the power supply to the electrical panel to avoid accidents.

Visual Inspection

A visual inspection is the first step in panel testing and involves carefully examining the panel’s physical condition.

Checking for Physical Damage

Inspect the panel for any visible signs of damage, such as cracks, rust, or loose connections.

Verifying Proper Labeling

Ensure that all circuits and breakers are clearly labeled for easy identification.

Thermal Imaging

Thermal imaging helps identify hotspots and areas of overheating within the panel.

Identifying Hotspots

Hotspots can indicate loose connections or components at risk of failure.

Detecting Overloading Issues

Thermal imaging can reveal overloaded circuits that might cause overheating.

Voltage Testing

Voltage testing is essential to ensure the proper functioning of circuits and voltage levels.

Measuring Voltage Levels

Check the voltage levels across each circuit to ensure they are within the acceptable range.

Verifying Phase Connections

Ensure that all phases are correctly connected to avoid phase imbalances.

Current Load Analysis

Analyzing the current load on each circuit helps identify potential overloads.

Analyzing Current Flow

Measure the current flow in each circuit to check for imbalances.

Balancing Load Distribution

Re-distribute loads among circuits to achieve a balanced electrical system.

Circuit Breaker Testing

Testing circuit breakers ensures they trip properly during overcurrent situations.

Testing Trip Times

Verify that the circuit breakers trip within an appropriate timeframe during fault conditions.

Checking for Proper Functioning

Ensure that all circuit breakers are working correctly, and replace faulty ones if necessary.

Ground Fault Testing

Ground fault testing is essential for detecting faults in the grounding system.

Verifying Grounding Systems

Ensure that the grounding connections are secure and effective.

Identifying Faults

Detect any ground faults that may cause electrical hazards.

Insulation Resistance Test

An insulation resistance test helps assess the integrity of insulation materials.

Measuring Insulation Integrity

Check the resistance between conductors and ground to identify potential insulation issues.

Detecting Potential Hazards

Identify any weak points in the insulation that might lead to electrical accidents.

Power Factor Examination

Assessing the power factor helps improve energy efficiency and reduce power wastage.

Understanding Power Factor

Understand the concept of power factor and its significance in electrical systems.

Correcting Power Factor Imbalance

Take corrective measures to balance the power factor and enhance efficiency.

Harmonic Analysis

Harmonics can affect the performance of electrical equipment and lead to inefficiencies.

Identifying Harmonic Distortion

Perform harmonic analysis to detect and quantify harmonic distortion.

Mitigating Harmonic Issues

Implement solutions to reduce harmonics and improve equipment performance.

Surge Protection Inspection

Surge protectors safeguard electrical equipment from voltage spikes.

Checking Surge Protectors

Inspect surge protectors for any damage or worn-out components.

Ensuring Effective Protection

Verify that surge protection devices are capable of handling potential surges.

Finalizing the Testing Process

After completing all the tests, take the following steps to conclude the process.

Documenting Results

Record all test results and observations for future reference.

Taking Corrective Actions

Address any identified issues promptly and efficiently.

Setting Up Maintenance Schedule

Establish a regular maintenance schedule to ensure ongoing safety and reliability.

Conclusion

Effective electrical panel testing is vital for maintaining a safe and reliable electrical system. Regular inspections and testing help prevent accidents, protect equipment, and promote energy efficiency. By following the comprehensive guide provided here, you can ensure the safety and efficiency of your electrical panels.

FAQs

- Why is electrical panel testing important? Regular testing helps identify potential issues and prevent electrical hazards.

- What tools are needed for electrical panel testing? Tools such as a multimeter, thermal imaging camera, and voltage tester are essential.

- Can I conduct electrical panel testing without shutting down power? No, shutting down power is necessary for safety during testing.

- How often should I test my electrical panels? It is recommended to test electrical panels at least once a year.

- What should I do if I find a fault during testing? If a fault is found, take corrective action immediately and consult a professional if needed.