Crucial Tests Unveiled: Ensuring Safety with Electrical Panel Testing

1. Introduction

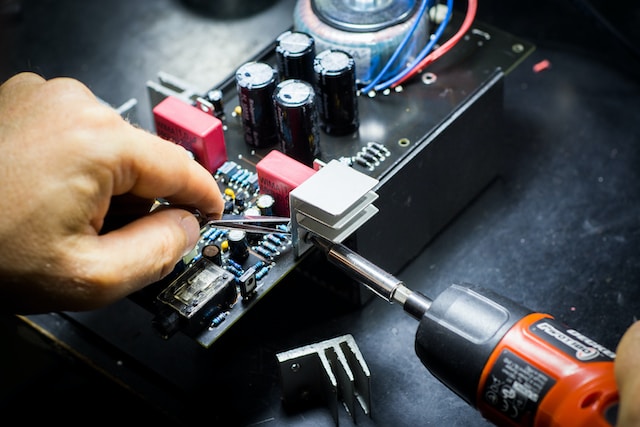

Electrical panel testing is a crucial aspect of ensuring the safety and reliability of electrical systems in both residential and commercial settings. By conducting regular tests on electrical panels, potential hazards can be identified, electrical fires can be prevented, and the overall efficiency of the electrical system can be improved. In this article, we will delve into the importance of electrical panel testing, discuss common issues that can arise with electrical panels, explore the benefits of testing, examine different types of electrical panel tests, and provide guidance on hiring professionals or performing basic tests yourself.

2. The Importance of Electrical Panel Testing

Electrical panel testing plays a vital role in maintaining the safety of a building’s electrical system. Panels act as the central hub that controls and distributes electricity throughout the premises. Over time, electrical panels can develop issues such as overloading, loose connections, corrosion, and outdated equipment, which can compromise their functionality and pose significant risks. Regular testing helps identify these problems before they escalate into hazardous situations.

3. Understanding Electrical Panels

3.1 Components of an Electrical Panel

An electrical panel consists of various components, including circuit breakers, fuses, main disconnect switches, bus bars, and grounding equipment. Each component serves a specific purpose in regulating and protecting the electrical system.

3.2 Function of an Electrical Panel

The primary function of an electrical panel is to receive electrical power from the utility company and distribute it safely to different circuits in a building. It also safeguards the electrical system by interrupting the flow of electricity in case of an overload or short circuit.

4. Common Issues with Electrical Panels

To ensure the safety and reliability of electrical panels, it’s essential to be aware of common issues that can arise. Some of these issues include:

4.1 Overloading

Overloading occurs when the electrical panel receives more electrical current than it can handle. This can lead to overheating, damaged equipment, and increased fire risk.

4.2 Loose Connections

Loose connections in an electrical panel can cause power fluctuations, flickering lights, and even electrical arcing. They can also create resistance and generate heat, potentially leading to electrical fires.

4.3 Corrosion

Corrosion, often caused by moisture or environmental factors, can affect the electrical panel’s conductors, connections, and components. Corroded parts may result in poor electrical conductivity, voltage drops, or complete circuit failure.

4.4 Outdated Equipment

Older electrical panels may not meet current safety standards or have the capacity to handle modern electrical demands. Outdated equipment increases the risk of electrical malfunctions and poses safety hazards.

5. The Benefits of Electrical Panel Testing

Regular electrical panel testing offers numerous benefits, including:

5.1 Identifying Potential Hazards

Thorough testing helps identify potential hazards in electrical panels, such as damaged components, loose connections, or signs of wear and tear. Identifying these issues early on allows for prompt repairs or replacements, preventing accidents and electrical failures.

5.2 Preventing Electrical Fires

Electrical fires can be devastating and life-threatening. By testing electrical panels, potential fire hazards can be identified and addressed promptly, reducing the risk of fire incidents.

5.3 Improving Electrical System Efficiency

Testing ensures that electrical panels are functioning optimally. Addressing any issues, such as overloading or loose connections, can improve the overall efficiency of the electrical system, resulting in reduced energy consumption and cost savings.

6. Types of Electrical Panel Tests

Various tests can be performed on electrical panels to evaluate their condition and functionality. Some common types of electrical panel tests include:

6.1 Visual Inspection

A visual inspection involves examining the electrical panel for any visible signs of damage, loose connections, corrosion, or outdated components. This test helps identify immediate issues that require attention.

6.2 Load Testing

Load testing involves assessing the electrical panel’s capacity to handle the maximum load it may encounter. By simulating real-world scenarios, load testing determines if the panel can operate safely under peak conditions.

6.3 Insulation Resistance Testing

Insulation resistance testing measures the electrical panel’s insulation resistance, which is crucial for preventing electrical leakage and ensuring proper electrical isolation. This test helps identify insulation breakdowns or potential short circuits.

6.4 Ground Fault Circuit Interrupter (GFCI) Testing

GFCI testing ensures that ground fault circuit interrupters are functioning correctly. These devices protect against electric shock by quickly shutting off power in the event of a ground fault.

6.5 Circuit Breaker Testing

Circuit breaker testing involves evaluating the performance and responsiveness of circuit breakers within the electrical panel. This test verifies their ability to interrupt current flow during overloads or short circuits.

electrical panel testing to ensure accurate and comprehensive assessments. When selecting a professional for electrical panel testing, consider the following factors:

7.1 Qualifications and Experience

Choose a professional who possesses the necessary qualifications and experience in electrical panel testing. Look for certifications or licenses that demonstrate their expertise in the field. Additionally, consider their experience working with similar types of electrical panels and systems.

7.2 Reputation and Reviews

Research the reputation of the professional or the company offering electrical panel testing services. Read reviews and testimonials from previous clients to gauge their reliability, professionalism, and quality of work. A reputable provider will have positive feedback and a track record of delivering satisfactory results.

7.3 Licensing and Insurance

Ensure that the professional or company holds the appropriate licenses and insurance coverage. Licensing ensures that they comply with industry standards and regulations. Insurance coverage protects you from any liability in case of accidents or damages that may occur during the testing process.

8. DIY Electrical Panel Testing Precautions

While some basic visual inspections can be performed by homeowners, it’s crucial to exercise caution and follow safety guidelines. Here are some precautions to keep in mind:

8.1 Safety First

Prioritize safety when performing any DIY electrical panel testing. Wear appropriate personal protective equipment (PPE), such as safety gloves and goggles, to protect yourself from electrical hazards.

8.2 Basic Visual Inspection

Perform a visual inspection of the electrical panel, looking for signs of damage, loose connections, or corrosion. However, refrain from touching any internal components or conducting in-depth testing without the necessary expertise.

8.3 Signs of Trouble

Educate yourself about the warning signs of electrical panel issues. These signs may include flickering lights, burning odors, tripping circuit breakers, or buzzing sounds. If you notice any of these indicators, it’s best to call a professional for further inspection.

8.4 Knowing When to Call a Professional

Recognize your limitations and know when it’s necessary to seek professional help. If you’re unsure about any aspect of electrical panel testing or encounter complex issues, it’s safer to rely on a qualified electrician or technician.

9. Conclusion

Electrical panel testing is a crucial aspect of maintaining a safe and reliable electrical system. By identifying potential hazards, preventing electrical fires, and improving system efficiency, testing ensures the optimal functioning of electrical panels. Whether you choose to hire a professional or perform basic inspections yourself, prioritizing safety and addressing issues promptly is essential for safeguarding your property and the people within it.

FAQs (Frequently Asked Questions)

- Is electrical panel testing necessary for residential properties? Yes, electrical panel testing is essential for residential properties to ensure safety and prevent potential hazards.

- How often should electrical panel testing be conducted? It is recommended to have electrical panel testing conducted at least once every 1 to 3 years, depending on the age and condition of the panel.

- Can I perform electrical panel testing myself without professional assistance? Basic visual inspections can be done by homeowners, but it’s crucial to exercise caution and call a professional for more in-depth testing and repairs.

- What are the potential risks of neglecting electrical panel testing? Neglecting electrical panel testing can lead to safety hazards, electrical fires, equipment damage, and inefficient electrical systems.

- How long does electrical panel testing typically take? The duration of electrical panel testing depends on various factors, including the size of the panel, the complexity of the system, and the extent of the testing required. A professional can provide a more accurate estimate based on your specific circumstances.