Safety Reinforced: Harnessing the Power of Earth Resistance Testing for Grounding Safety

Introduction

Grounding plays a crucial role in electrical systems by providing a safe pathway for electrical currents to flow to the ground. It ensures the protection of personnel and equipment from electrical faults, transient surges, and lightning strikes. Earth resistance testing is a vital process that helps assess the integrity and effectiveness of grounding systems. In this article, we will explore the significance of earth resistance testing, various testing methods, benefits, equipment used, step-by-step testing procedures, common challenges, best practices, and its applications in different industries.

Understanding Grounding and Its Importance

Proper grounding is essential to maintain electrical safety. It involves connecting electrical systems to the earth using conductors, such as grounding electrodes. Grounding helps prevent electrical shock, protects equipment from damage, and ensures electrical stability. Without effective grounding, electrical faults can lead to severe consequences, including fires, equipment failures, and even fatal accidents.

The Role of Earth Resistance Testing in Grounding Safety

Earth resistance testing is a fundamental aspect of ensuring the safety and reliability of grounding systems. It measures the resistance offered by the earth electrode to the flow of current. By conducting regular earth resistance tests, engineers and technicians can identify potential issues and take corrective measures to maintain optimal grounding conditions.

Types of Grounding Systems

There are different types of grounding systems commonly used based on specific requirements. These include solid grounding systems, resistance grounding systems, and reactance grounding systems. Each type has its own advantages and applications, depending on factors such as fault current levels, system voltages, and operational requirements.

Solid Grounding Systems

Solid grounding systems provide a direct connection between the neutral point of the electrical system and the earth. They offer high fault current levels and are commonly used in low-voltage electrical systems.

Resistance Grounding Systems

Resistance grounding systems limit the fault current by connecting the neutral point to the earth through a resistor. They provide increased safety and reduce the risk of electrical shock and equipment damage.

Reactance Grounding Systems

Reactance grounding systems use inductive or capacitive devices to limit fault current. They are often employed in high-voltage systems, where minimizing the fault current is crucial for the overall stability of the electrical network.

Earth Resistance Testing Methods

Earth resistance testing can be performed using different methods based on the specific requirements of the grounding system. The three most commonly used testing methods are two-point testing, three-point testing, and four-point testing.

Two-Point Testing

Two-point testing involves injecting a known test current at one point and measuring the voltage drop at another point. The resistance is then calculated using Ohm’s law. This method is suitable for small grounding systems and provides a basic assessment of the earth resistance.

Three-Point Testing

Three-point testing utilizes an additional current electrode along with the injection and measurement electrodes used in two-point testing. This method provides more accurate results by accounting for the effects of soil resistivity.

Four-Point Testing

Four-point testing, also known as the “Wenner method,” involves using four evenly spaced electrodes to inject current and measure voltage drop. It offers highly accurate results and is commonly used for large grounding systems or when precise measurements are required.

Benefits of Earth Resistance Testing

Earth resistance testing offers several significant benefits, making it an indispensable process for maintaining grounding safety.

Ensuring Personnel Safety

By regularly conducting earth resistance tests, organizations can ensure the safety of their personnel. Testing helps identify any faults or deteriorations in the grounding system that may pose a risk to individuals working in proximity to electrical equipment.

Preventing Equipment Damage

Grounding faults can lead to equipment failures, resulting in costly repairs or replacements. Earth resistance testing helps detect any abnormalities in the grounding system, allowing for timely maintenance and preventing potential damage to equipment.

Compliance with Safety Standards

Many industries are subject to specific safety standards and regulations. Earth resistance testing helps organizations meet these requirements, ensuring they remain compliant with industry standards and guidelines.

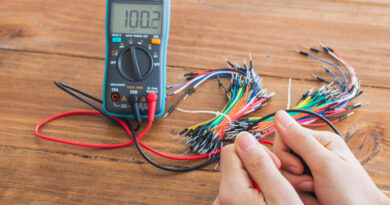

Earth Resistance Testing Equipment

To perform earth resistance testing accurately, specialized equipment is required. Several types of equipment are commonly used for this purpose.

Earth Ground Testers

Earth ground testers are portable devices that measure earth resistance using different testing methods. They typically offer features such as data logging, graphical displays, and built-in safety features.

Clamp-On Ground Resistance Testers

Clamp-on ground resistance testers provide a non-intrusive method for measuring earth resistance. They can clamp onto grounding conductors and measure the resistance without disconnecting the system.

Earth Resistivity Meters

Earth resistivity meters are used to measure the resistivity of the soil. This information helps engineers understand the soil conditions and design efficient grounding systems.

Step-by-Step Guide for Conducting Earth Resistance Testing

Conducting earth resistance testing requires a systematic approach to ensure accurate and reliable results. The following steps outline the process:

- Preparing for the Test: Gather the necessary equipment, review safety precautions, and obtain any relevant documentation.

- Setting Up the Testing Equipment: Connect the testing equipment according to the selected testing method and configure the required settings.

- Performing the Test: Inject the test current into the grounding system and measure the voltage drop at the appropriate points.

- Analyzing the Test Results: Calculate the earth resistance based on the measured values and compare them against acceptable limits. Interpret the results to identify any issues or areas for improvement.

Common Challenges in Earth Resistance Testing

While performing earth resistance testing, certain challenges can affect the accuracy of the results. It is important to be aware of these challenges and mitigate their impact as much as

possible. Here are some common challenges encountered during earth resistance testing:

Environmental Factors

Environmental factors such as temperature, humidity, and atmospheric conditions can influence the accuracy of earth resistance testing. Extreme weather conditions or variations in soil moisture content can affect the electrical conductivity of the soil, leading to inconsistent test results. It’s important to consider these factors and make necessary adjustments or repeat tests under more favorable conditions if required.

Soil Conditions

The resistivity of the soil plays a significant role in earth resistance testing. Different types of soil, such as clay, sand, or rocky terrain, have varying resistivity levels. Soil moisture content, salinity, and composition can also affect resistivity. Conducting tests in different locations or using different electrode configurations can help account for variations in soil conditions and ensure accurate results.

Interference and Noise

Electromagnetic interference (EMI) and electrical noise from nearby equipment or power sources can introduce errors during earth resistance testing. These external factors can distort measurements and lead to misleading results. To minimize interference, it is crucial to choose testing locations away from high-power equipment and electrical cables. Shielding the testing equipment and using proper grounding techniques can also help mitigate interference.

Best Practices for Reliable Earth Resistance Testing

To ensure reliable and accurate earth resistance testing, it is important to follow best practices. Here are some key recommendations:

Regular Maintenance and Calibration

Maintain and calibrate the testing equipment regularly to ensure accurate measurements. Periodic checks and calibration by qualified professionals help maintain the reliability and precision of the testing instruments. Adhering to manufacturer guidelines for maintenance and calibration is essential for obtaining reliable results.

Proper Electrode Installation

Proper installation of the electrodes is crucial for obtaining accurate earth resistance measurements. Ensure good electrical contact between the electrodes and the soil. Clean the electrode surfaces to remove any corrosion or dirt that may affect the measurements. Using high-quality, durable electrodes that are suitable for the specific soil conditions is also important.

Data Documentation and Record Keeping

Document all test procedures, measurements, and results systematically. Maintain a record of previous tests and measurements for future reference and comparison. Proper documentation allows for easy analysis of trends and helps identify any long-term changes or deteriorations in the grounding system.

Earth Resistance Testing in Different Industries

Earth resistance testing is essential across various industries to ensure safety and proper functioning of electrical systems. Here are some examples of industries where earth resistance testing is commonly employed:

Power and Utilities

In the power and utilities sector, earth resistance testing is crucial for maintaining the integrity of power distribution networks. It helps ensure reliable grounding of transmission towers, substations, and electrical equipment, reducing the risk of electrical faults and ensuring the safety of personnel working in these environments.

Telecommunications

Telecommunications infrastructure relies on proper grounding to protect sensitive equipment from electrical surges and maintain signal integrity. Earth resistance testing is performed to verify the effectiveness of grounding systems in telecommunication towers, data centers, and network facilities.

Industrial and Manufacturing

In industrial and manufacturing settings, earth resistance testing is vital to protect personnel, equipment, and processes. Proper grounding minimizes the risk of electrical hazards, equipment damage, and production downtime. Earth resistance testing is performed on grounding systems in factories, refineries, chemical plants, and other industrial facilities.

Case Studies: Success Stories of Earth Resistance Testing

Case Study 1: Enhancing Safety in a Petrochemical Plant

In a large petrochemical plant, regular earth resistance testing was implemented to ensure the safety of personnel and prevent equipment failures. By identifying and rectifying grounding system faults, the plant significantly reduced the risk of electrical hazards, enhancing the overall safety of the facility.

Case Study 2: Improving Power Distribution Reliability

A utility company conducted comprehensive earth resistance testing on its power distribution network. The test results revealed several areas with high resistance, indicating poor grounding conditions. By addressing these issues and optimizing the grounding systems, the company improved the reliability of its power distribution, minimizing outages and enhancing customer satisfaction.

Conclusion

Earth resistance testing is a critical process for ensuring grounding safety and the reliable operation of electrical systems. By assessing the integrity of grounding systems and identifying potential issues, organizations can mitigate electrical hazards, protect equipment, and comply with safety standards. Implementing best practices, using appropriate testing methods, and addressing common challenges will help achieve accurate and reliable results. From power utilities to telecommunications and various industries, earth resistance testing plays a vital role in safeguarding personnel, equipment, and critical infrastructure.

FAQs (Frequently Asked Questions)

1. How often should earth resistance testing be performed?

The frequency of earth resistance testing depends on several factors, including industry regulations, equipment usage, and environmental conditions. It is generally recommended to conduct testing at regular intervals, such as annually or biennially. However, in high-risk industries or environments, more frequent testing may be necessary.

2. Can earth resistance testing be performed on existing grounding systems?

Yes, earth resistance testing can be performed on existing grounding systems. It helps evaluate the effectiveness of the current grounding system and identify any faults or improvements needed. Regular testing ensures ongoing safety and reliability.

3. Is earth resistance testing only necessary for large-scale installations?

No, earth resistance testing is essential for both small-scale and large-scale installations. Proper grounding is crucial for any electrical system, regardless of its size. Conducting earth resistance tests helps identify potential issues and maintain a safe operating environment.