Safety Reinforced: Harnessing the Power of Electrical Panel Testing for a Secure Future

Introduction

Electrical panels are crucial components of any building’s electrical system. They distribute electricity to various circuits, ensuring smooth and safe functioning of electrical appliances. However, over time, electrical panels can deteriorate, leading to potential hazards such as electrical fires and equipment damage. To prevent such risks and ensure a secure future, it is essential to conduct regular electrical panel testing.

I. Electricity Power

In today’s technologically advanced world, electricity powers almost every aspect of our lives. From powering our homes to running industrial machinery, electricity is the lifeblood of modern society. With such heavy reliance on electricity, it becomes paramount to prioritize safety measures, and electrical panel testing plays a pivotal role in achieving that goal.

II. Understanding Electrical Panels

A. What are electrical panels?

Electrical panels, also known as distribution boards or breaker boxes, are control centers that manage and distribute electricity throughout a building. They receive electricity from the main power supply and divide it into individual circuits, which then power various appliances and devices.

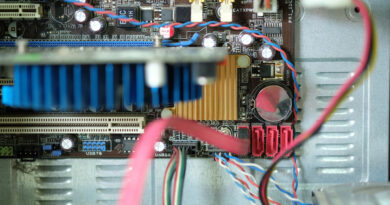

B. Components of an electrical panel

An electrical panel consists of several key components, including circuit breakers, fuses, bus bars, and wires. Circuit breakers protect the circuits from overloads and short circuits by automatically shutting off the flow of electricity when necessary. Fuses perform a similar function but need replacement when they blow. Bus bars distribute electricity from the main supply to the individual circuits, and wires transmit the electrical current.

III. The Need for Electrical Panel Testing

A. Ensuring safety and compliance

Regular electrical panel testing is crucial to maintain the safety and compliance standards of a building. Over time, electrical panels can develop faults, loose connections, or worn-out components, increasing the risk of electrical accidents. Testing helps identify these issues and rectify them before they lead to hazardous situations.

B. Identifying potential issues

Electrical panel testing allows professionals to detect potential issues that may not be immediately visible. Loose connections, corrosion, and damaged components can all go unnoticed without proper inspection. Identifying these issues early on helps prevent future electrical problems.

IV. Types of Electrical Panel Testing

A. Visual inspection

Visual inspection is the first step in electrical panel testing. It involves examining the panel for any visible signs of damage, such as burnt marks, loose wires, or overheating components. A thorough visual inspection provides initial insights into the overall condition of the panel.

B. Electrical measurements

Electrical measurements involve testing the voltage, current, and resistance within the electrical panel. This step helps assess the panel’s performance, identify any irregularities, and ensure that it meets the required electrical standards.

C. Thermal imaging

Thermal imaging uses infrared technology to detect temperature variations in the electrical panel. It can identify hotspots, loose connections, and potential points of failure that may not be visible through visual inspection. By pinpointing these areas, necessary repairs or replacements can be carried out promptly.

V. Benefits of Regular Electrical Panel Testing

A. Preventing electrical fires

Electrical fires pose a significant risk to life and property. Regular electrical panel testing helps identify potential fire hazards, such as overheating components or faulty wiring, allowing for timely repairs or replacements. By addressing these issues proactively, the risk of electrical fires can be significantly reduced.

B. Minimizing downtime

Electrical panel failures can result in downtime and disruption of essential services. Regular testing ensures that the panels are in optimal condition, minimizing the chances of unexpected failures and reducing downtime. This is particularly crucial in commercial and industrial settings where uninterrupted power supply is essential.

C. Extending the lifespan of electrical panels

Proactive testing and maintenance significantly extend the lifespan of electrical panels. By identifying and addressing issues early on, the overall wear and tear on the panels are reduced. This helps maximize their longevity and reduces the need for costly replacements.

VI. Hiring a Professional for Electrical Panel Testing

A. Qualifications and expertise

When it comes to electrical panel testing, it is advisable to hire a professional with the necessary qualifications and expertise. Licensed electricians or specialized electrical service providers possess the knowledge and skills required to conduct comprehensive panel testing. Their experience ensures thorough inspections and accurate assessments.

B. Choosing the right service provider

Selecting the right service provider is essential for effective electrical panel testing. Consider factors such as reputation, customer reviews, and certifications before making a decision. A reliable and reputable service provider will ensure thorough testing and provide detailed reports, outlining any issues and recommended solutions.

VII. DIY Electrical Panel Testing

A. Safety precautions

While professional testing is recommended, homeowners can also perform basic electrical panel tests. However, it is crucial to prioritize safety and take necessary precautions. Ensure that the main power supply is turned off, wear protective gear, and follow all safety guidelines and instructions.

B. Simple tests homeowners can perform

Homeowners can perform visual inspections by looking for signs of damage or overheating within the electrical panel. They can also test individual circuits by turning them on and off to ensure proper functioning. However, it is essential to remember that complex issues require professional expertise, and homeowners should not attempt repairs or replacements themselves.

VIII. Conclusion

Electrical panel testing is an integral part of ensuring safety, compliance, and optimal performance. By regularly inspecting and testing electrical panels, potential hazards can be identified and addressed promptly, preventing accidents and minimizing downtime. Whether through professional services or basic DIY inspections, taking proactive measures in panel testing contributes to a secure future.

FAQs

1. Why is electrical panel testing important?

Electrical panel testing is important to ensure the safety, compliance, and optimal performance of electrical panels. It helps identify potential issues, prevent electrical fires, and minimize downtime.

2. Can I perform electrical panel testing myself?

While homeowners can perform basic visual inspections and simple tests, it is recommended to hire a professional for comprehensive electrical panel testing. Professionals have the necessary expertise to identify complex issues and ensure accurate assessments.

3. How often should electrical panel testing be done?

The frequency of electrical panel testing depends on various factors such as the age of the building, the type of electrical system, and local regulations. It is generally recommended to conduct testing at least once every 1-3 years or as advised by professionals.