Unlocking the Potential: Mastering Electrical Testing for Safety and Performance

Introduction

Testing is essential for verifying the functionality and safety of electrical systems. Understanding the foundations of electrical testing will help you make wise decisions and avoid potential risks, whether you’re a homeowner, an electrician, or a business owner. We will examine the fundamental ideas and procedures of electrical testing in this in-depth manual, arming you with the information you need to maximize the efficiency of your electrical systems.

Why Electrical Testing Matters

Electrical systems are the lifeblood of modern society. From powering our homes to running complex industrial machinery, electricity enables countless aspects of our daily lives. However, faulty or compromised electrical systems can pose significant risks, including electrical shocks, fires, and equipment damage. This is where electrical testing comes into play.

Ensuring Safety

The foremost objective of electrical testing is to ensure safety. By conducting regular inspections and tests, you can identify and rectify potential electrical hazards before they escalate. This proactive approach minimizes the risk of electrical accidents, protecting both people and property.

Optimizing Performance

In addition to safety, electrical testing is essential for optimizing the performance of electrical systems. By assessing the integrity of wiring, connections, and components, you can identify inefficiencies, voltage drops, and other issues that may compromise the system’s performance. Through accurate testing and subsequent improvements, you can enhance energy efficiency, reduce downtime, and maximize the lifespan of electrical equipment.

Types of Electrical Testing

To effectively master electrical testing, it is essential to familiarize yourself with the different types of tests commonly employed. Let’s explore some of the key testing methods:

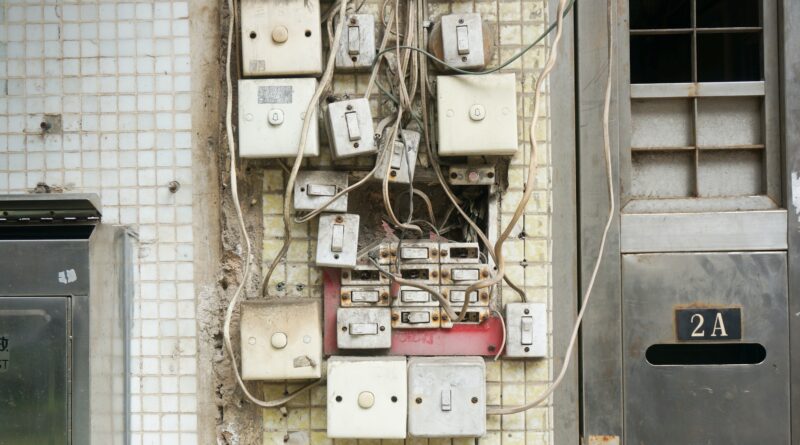

1. Visual Inspection

Visual inspection forms the foundation of any electrical testing regimen. This involves carefully examining electrical components, wiring, and connections to identify visible signs of damage, wear, or loose connections. Visual inspection is a simple yet powerful technique that can often reveal immediate issues.

2. Voltage Testing

Voltage testing is used to measure the electrical potential difference between two points in a circuit. This test helps ensure that the voltage levels are within the safe operating range. By utilizing voltmeters, professionals can identify overvoltage or undervoltage conditions, which can indicate faulty components or improper wiring.

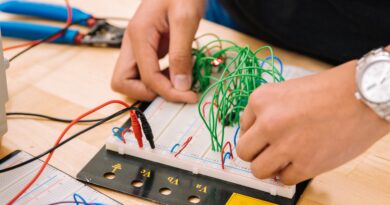

3. Continuity Testing

Continuity testing is employed to check the integrity of electrical pathways and connections. By measuring the continuity of electrical circuits, professionals can identify any breaks or interruptions that may impede the flow of electricity. This test is particularly useful for locating faulty switches, fuses, or damaged wiring.

4. Insulation Resistance Testing

Insulation resistance testing is designed to evaluate the condition of insulation materials surrounding electrical conductors. By measuring the resistance to electrical current flow, professionals can identify potential insulation breakdowns, moisture ingress, or other issues that may compromise safety and performance. Insulation resistance testing is crucial in preventing electrical leakage and ensuring the longevity of electrical systems.

5. Power Quality Analysis

Power quality analysis involves a comprehensive assessment of various electrical parameters, including voltage stability, harmonics, and frequency fluctuations. By analyzing power quality, professionals can identify and address issues that may result in poor performance, equipment malfunctions, or even damage to sensitive electronics. This test is particularly relevant for commercial and industrial settings where power quality is critical.

Best Practices for Effective Electrical Testing

Now that we have explored the fundamental types of electrical testing, let’s delve into some best practices to ensure accurate and reliable results:

1. Follow Safety Protocols

Safety should be the top priority when conducting electrical testing. Always wear appropriate personal protective equipment (PPE), including insulated gloves, safety goggles, and protective clothing. Ensure that the testing environment is free from potential hazards and follow established safety protocols to minimize the risk of accidents.

2. Use Calibrated Equipment

To obtain accurate measurements, it is crucial to use properly calibrated testing equipment. Regularly calibrate and maintain your instruments to ensure their accuracy and reliability. Faulty or inaccurate equipment can lead to misleading results and compromise the effectiveness of your testing efforts.

3. Document and Track Results

Maintaining detailed documentation of your testing activities is essential for record-keeping and future reference. Document the test procedures, measurements, and any identified issues or recommendations. This documentation will serve as a valuable resource for troubleshooting, tracking system performance over time, and demonstrating compliance with safety regulations.

4. Stay Updated with Codes and Standards

Electrical codes and standards evolve over time to incorporate new technologies and safety practices. As a competent electrical tester, it is essential to stay updated with the latest codes and standards relevant to your industry. Regularly review and familiarize yourself with the guidelines provided by reputable organizations such as the National Electrical Code (NEC) or the International Electrotechnical Commission (IEC).

5. Consult Professionals

While basic electrical testing can be performed by knowledgeable individuals, complex systems and specialized equipment may require the expertise of professional electrical engineers or certified technicians. When in doubt or dealing with intricate electrical systems, it is advisable to seek professional assistance to ensure accurate testing and reliable results.

Conclusion: Empowering Electrical Testing for Safety and Performance

In conclusion, mastering electrical testing is paramount for ensuring the safety and optimal performance of electrical systems. By understanding the different types of tests and implementing best practices, you can unlock the full potential of your electrical infrastructure. Remember, electrical testing is not just a regulatory requirement; it is a proactive approach that safeguards lives, property, and enhances efficiency. Stay informed, stay safe, and let electrical testing be the cornerstone of your electrical endeavors