Unveiling the Truth: Insights from Electrical Testing in Noida for a Safer Future

Introduction

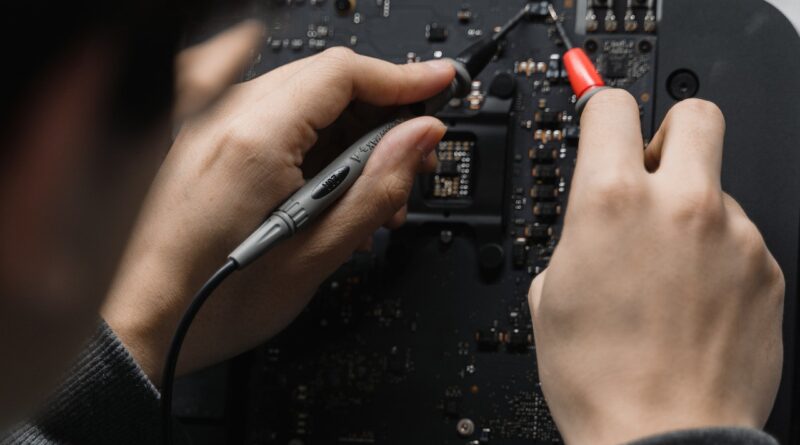

Electrical testing plays a crucial role in ensuring the safety and reliability of electrical systems. It involves various techniques and procedures to evaluate the performance and integrity of electrical installations. In Noida, a city known for its rapid urbanization and industrial growth, electrical testing holds significant importance in safeguarding lives and properties. This article explores the insights gained from electrical testing in Noida and its contribution to creating a safer future.

Importance of Electrical Testing

Electrical testing is a proactive approach to identify potential faults, inefficiencies, or safety hazards in electrical systems. By conducting regular tests, technicians can detect and address issues before they escalate into major problems, thereby minimizing the risk of electrical accidents, fires, or equipment failures. It helps ensure compliance with safety standards, maintain operational efficiency, and prolong the lifespan of electrical installations.

Understanding Electrical Testing

3.1 Types of Electrical Testing

Electrical testing encompasses various types of assessments and measurements. Some common types include:

H1 Heading: Insulation Resistance Testing

Insulation resistance testing is performed to assess the quality and effectiveness of insulation materials used in electrical systems. It helps detect any insulation breakdown or leakage that may compromise the safety and performance of the system.

H2 Heading: Earth Leakage Testing

Earth leakage testing measures the electrical current leaking to the earth from a system. It is crucial for detecting faults that could result in electric shock hazards or damage to sensitive equipment.

H2 Heading: Load Testing

Load testing involves assessing the performance of electrical systems under normal operating conditions. It verifies whether the system can handle the expected load without any issues, ensuring its reliability and safety.

3.2 Benefits of Electrical Testing

Electrical testing offers several benefits, including:

- Enhanced safety for individuals and properties

- Prevention of electrical accidents, fires, and equipment failures

- Compliance with safety regulations and standards

- Increased operational efficiency and reliability

- Cost savings through early detection of faults and preventive maintenance

Electrical Testing in Noida

4.1 Safety Regulations in Noida

Noida has implemented stringent safety regulations to ensure the well-being of its residents and businesses. These regulations mandate regular electrical testing to identify and rectify potential hazards, ensuring compliance with safety codes and standards.

4.2 Role of Electrical Testing in Noida

Electrical testing plays a pivotal role in Noida’s safety infrastructure. It helps identify faulty wiring, outdated equipment, inadequate grounding, or other electrical issues that may pose risks to individuals and properties. By conducting comprehensive tests, technicians can assess the health of electrical systems, pinpoint potential weaknesses, and recommend necessary repairs or upgrades.

Ensuring Safety through Electrical Testing

5.1 Routine Testing and Maintenance

Routine electrical testing and maintenance are essential to ensure the ongoing safety and optimal performance of electrical systems. Regular inspections, checks, and tests help identify wear and tear, loose connections, or other issues that may compromise the integrity of the system.

5.2 Periodic Inspection and Testing

Periodic inspection and testing involve more in-depth assessments of electrical systems at specified intervals. This comprehensive evaluation helps identify hidden faults, deterioration, or non-compliance with safety standards. It is particularly important for older buildings or installations that may have degraded over time.

5.3 Importance of Proper Grounding

Proper grounding is crucial for electrical safety. Through testing, technicians can verify the effectiveness of grounding systems, ensuring the dissipation of excess electrical energy and minimizing the risk of electric shocks or damage to equipment.

Common Electrical Testing Techniques

6.1 Insulation Resistance Testing

Insulation resistance testing involves measuring the resistance between conductors and insulation materials. This test helps identify any degradation or breakdown of insulation, which could lead to short circuits, electrical shocks, or fires.

6.2 Earth Leakage Testing

Earth leakage testing measures the amount of current flowing to the earth from a system. By detecting and addressing excessive leakage, this test prevents electric shocks, protects sensitive equipment, and ensures compliance with safety regulations.

6.3 Load Testing

Load testing evaluates the performance of electrical systems under normal operating conditions. It involves applying a predetermined load to assess the system’s response, stability, and capacity. Load testing helps identify potential issues such as voltage drops, overheating, or inadequate capacity.

Hiring Professional Electrical Testing Services

7.1 Qualifications and Experience

When hiring electrical testing services, it is essential to consider the qualifications and experience of the technicians. Look for professionals who possess relevant certifications, industry knowledge, and a track record of successfully conducting electrical tests.

7.2 Accreditation and Certification

Choose a service provider that holds appropriate accreditations and certifications. This ensures that they adhere to recognized standards and best practices in electrical testing, offering reliable and accurate assessments.

7.3 References and Reviews

Before finalizing a service provider, check for references and reviews from previous clients. This feedback can give you insights into their professionalism, reliability, and the quality of their services.

The Future of Electrical Testing

8.1 Advancements in Electrical Testing Technology

Advancements in technology are revolutionizing electrical testing. From sophisticated testing equipment to automated data analysis, these advancements enhance accuracy, efficiency, and effectiveness. The future holds promising developments that will further improve electrical testing procedures.

8.2 Integration of IoT in Electrical Testing

The integration of the Internet of Things (IoT) in electrical testing enables real-time monitoring, predictive maintenance, and data-driven insights. Connected sensors, devices, and analytics platforms provide valuable information to optimize performance, prevent failures, and enhance safety.

through Electrical Testing

Predictive maintenance is an emerging trend in electrical testing. By harnessing data analytics and predictive algorithms, electrical systems can be continuously monitored to detect potential failures before they occur. This proactive approach allows for timely repairs or replacements, minimizing downtime, and preventing costly disruptions.

The utilization of machine learning and artificial intelligence further enhances the capabilities of predictive maintenance. These technologies can analyze vast amounts of data, identify patterns, and provide accurate predictions regarding the health and performance of electrical systems. This not only increases safety but also optimizes maintenance schedules and reduces unnecessary expenses.

With the integration of predictive maintenance in electrical testing, businesses and homeowners in Noida can enjoy greater peace of mind, knowing that their electrical systems are continuously monitored and any potential issues will be addressed proactively.

Conclusion

Electrical testing plays a crucial role in Noida’s journey towards a safer future. By conducting regular tests and inspections, potential hazards and faults can be identified and rectified in a timely manner, ensuring the safety of individuals and properties. From routine maintenance to comprehensive inspections, electrical testing provides invaluable insights into the health and reliability of electrical systems.

As technology continues to advance, the future of electrical testing looks promising. Advancements such as IoT integration and predictive maintenance will further enhance the effectiveness and efficiency of electrical testing, enabling proactive measures to prevent failures and optimize performance.

FAQs

- Can electrical testing prevent electrical accidents?

- Yes, electrical testing helps identify potential hazards and faults, allowing for timely repairs or upgrades to prevent accidents.

- How often should electrical testing be performed?

- The frequency of electrical testing depends on various factors, including the type of installation and safety regulations. It is generally recommended to conduct periodic inspections and testing at regular intervals, typically every few years.

- Is electrical testing mandatory in Noida?

- Noida has implemented safety regulations that mandate regular electrical testing for certain types of installations to ensure compliance with safety standards.

- What are the consequences of neglecting electrical testing?

- Neglecting electrical testing can lead to increased risks of electrical accidents, fires, equipment failures, and non-compliance with safety regulations.

- Can I perform electrical testing myself?

- Electrical testing requires specialized knowledge, skills, and equipment. It is highly recommended to hire professional electrical testing services to ensure accurate and reliable results.